Quality without compromise

All product lines guarantee outstanding performance.

With the privileged access you will be able to download additional materials as you explore our site, if you do not yet have access you can request it here.

We see cool technology as a powerful and versatile tool

to make our lives easier, safer and more enjoyable.

Thanks to its experience, Samaref has been able to face the changes of the market and the challenges of the new millennium, investing significant resources in technological innovation and continuous improvement.

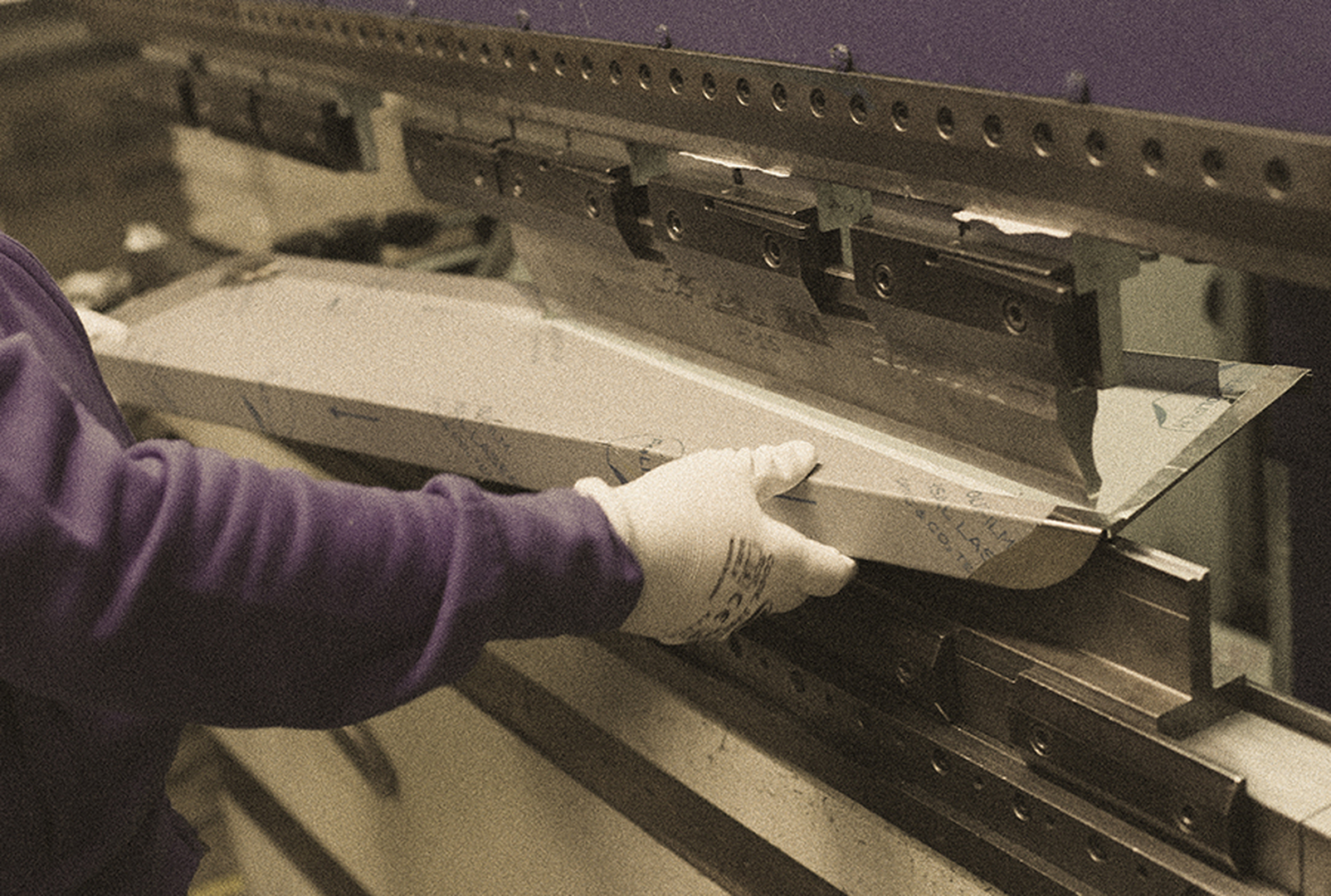

STAF was founded and began its activity in the design, cutting, stamping and various processing of steel.

The first production line for food storage cabinets is launched.

The Samaref brand is born.

Samaref launches the new meat ripening cabinet.

Launch of Ergon.

The first multifunctional blast chiller dedicated to restaurants, patisseries and ice-cream parlours.

Ergon evolves and Talent is born, the first multifunction blast chiller with intelligent linked cycles.

The chocolate cabinet with the lowest percentage humidity variation on the market.

The first ALL-IN-ONE pastry cabinet, all versatility in one machine.

The Sassaroli family is actively involved in the R&D and industrialisation processes, guaranteeing flexibility and proximity to the market.

Cool like the Samaref team.

Cool like the product design.

Instinct like the innate strength that drives us towards new goals.

Instinct like the passion for coolness that protects food.

The advantage of a professional service that is always close at hand.

More than 1300 distributors, more than 150 Samaref-trained technical service centres, more than 500 products distributed in more than 70 countries worldwide.

An ideal solution for every customer and every need,

with best-in-class performance.

All product lines guarantee outstanding performance.

Designed and tested in extreme conditions.

We believe that making work easier and more efficient leaves room for our customers' creativity.

Designed to last!

Samaref products are conceived, designed, manufactured and tested to meet customer needs, guaranteeing peace of mind and consistent performance over time.

The entire production process is carried out in-house, from sheet metal machining to foaming, assembly, functional testing and packaging.