Always one

step forward

Offer a greater number of dishes on the menu and reduce customer waiting time at the table by always offering healthy and natural food.

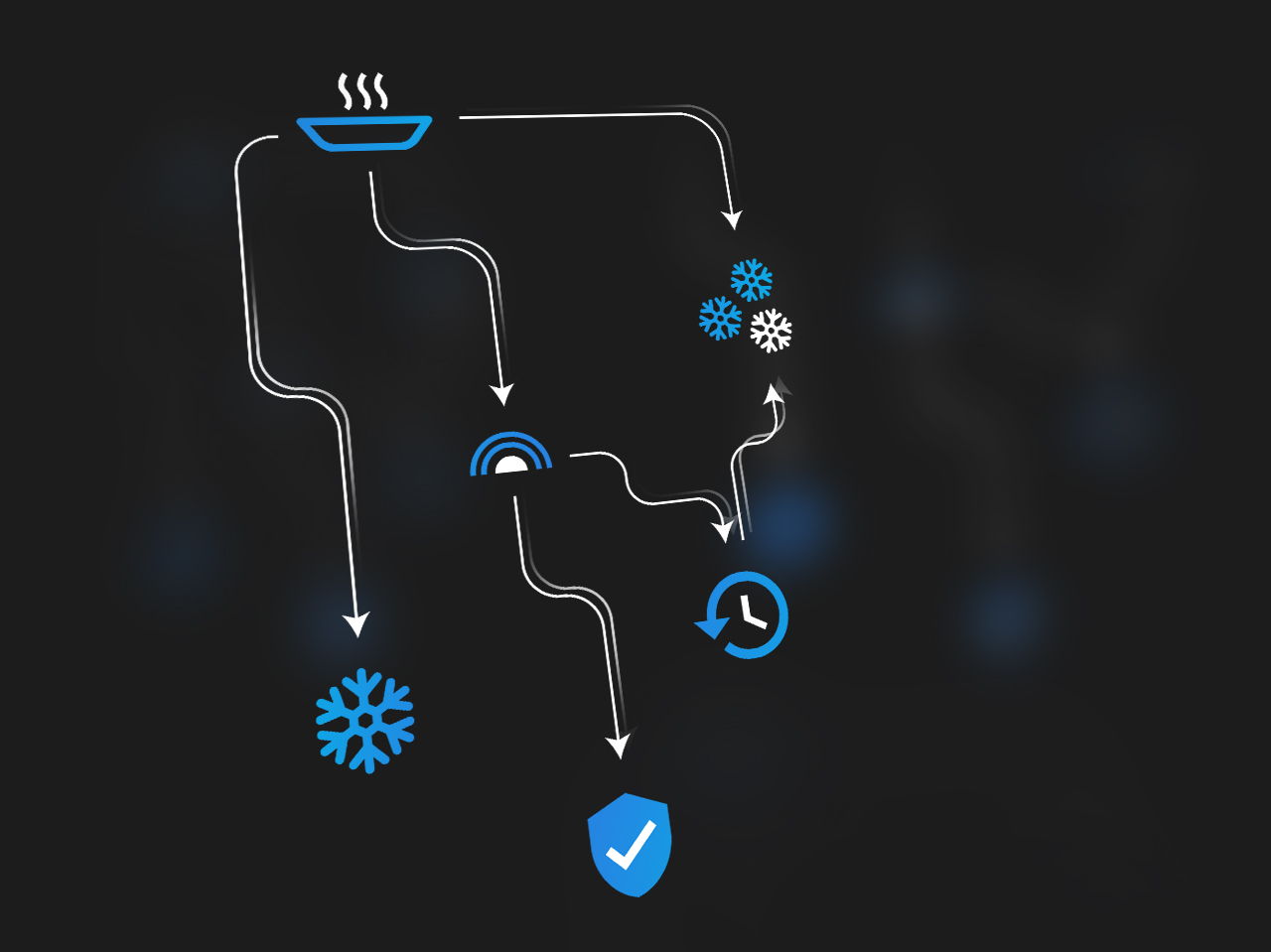

Blast chilling and Blast freezing

In a very short time, it blast chills and freezes fresh or cooked food to the core.

Slow cooking

It cooks food at a low temperature, evenly and in large quantities.

Retarding proofing

Regulates and controls leavening, optimising times and schedules according to your needs.

Thawing

Quickly defrost your dishes only when they are ordered, reducing waste and optimising profits.

Pasteurization

Increases storage time safely by eliminating pathogenic microorganisms.

Dehydration

Gently dehydrates and dries food, extending its shelf life.

Holding +65°C

Warm food, ready to serve for the duration of the service.

Conservation +6°C

Preserves food perfectly, ensuring maximum food safety.

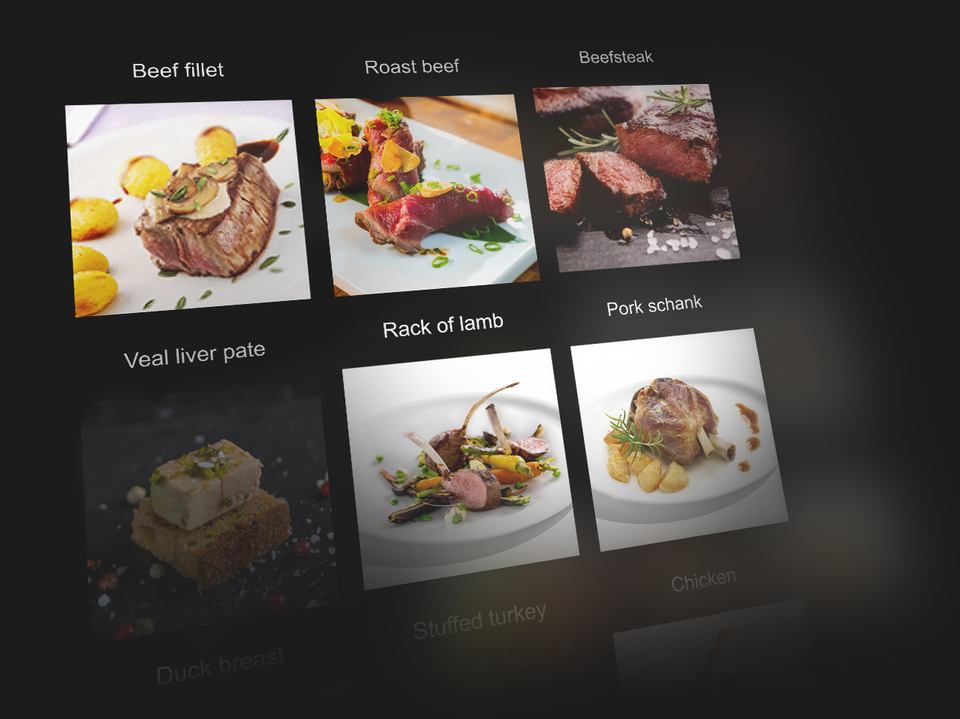

A recipe book designed for you

A rich recipe book at your service, with cycles designed to speed up your work, guarantee high quality standards and give space to your imagination.

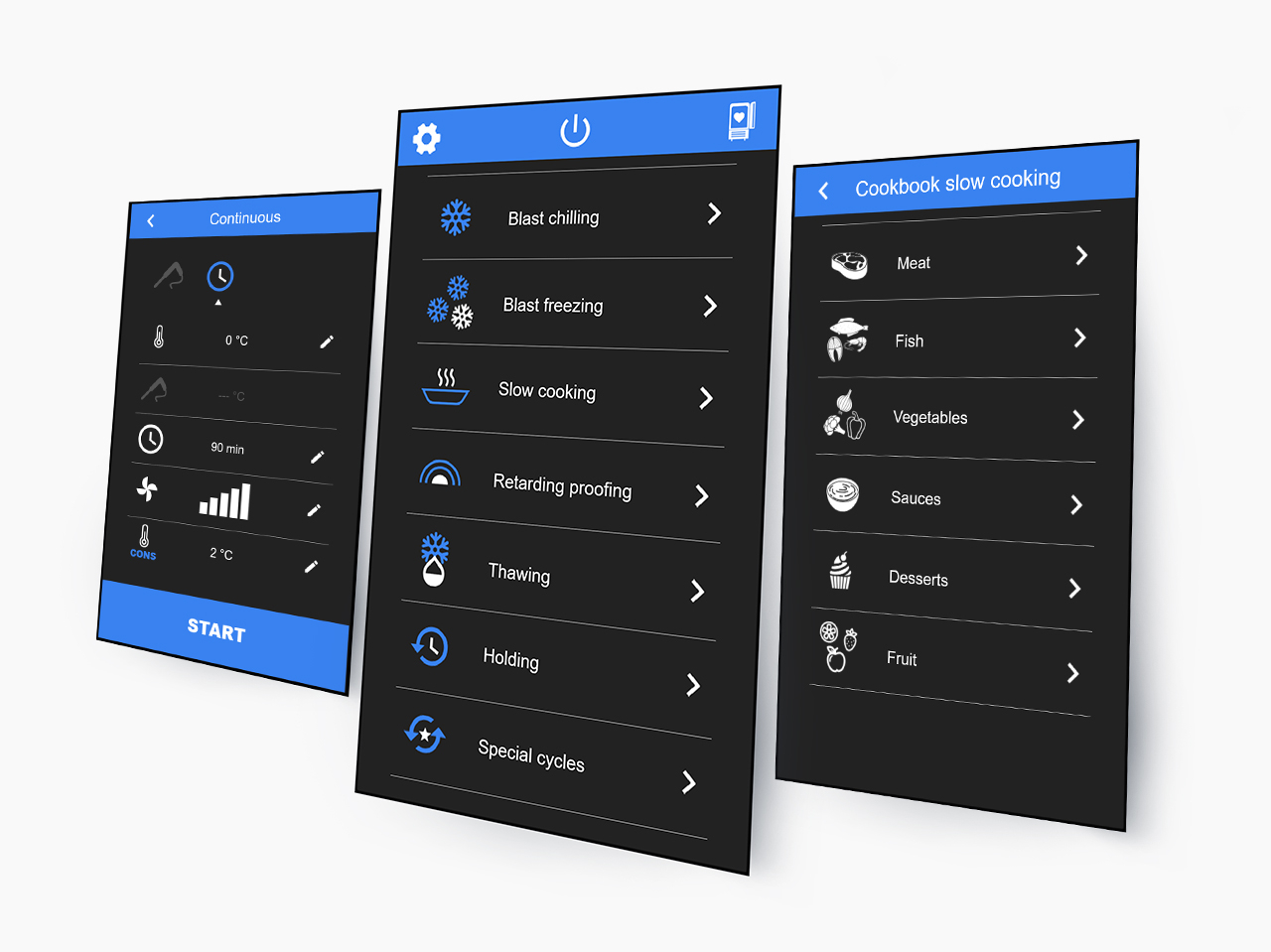

Display touch 7”

Simple and intuitive multilanguage graphic interface.

- Up to 100 storable

programs - Hard and soft cycles

- List of favorite programs

- Haccp alarms

- Preloaded recipes

- Multilingual

IT | EN | FR | DE | ES | PT | RU

Robust, one-piece structure

Solid structure made entirely of 304 stainless steel with 80 mm insulation thickness. The ramp, supplied, facilitates entry and exit of the trolley.

Solutions for

your success

Plan

the job

Organize the workload of the staff and equipment with a remarkable saving on preparation costs.

Production

times

Quickly cool and freeze the hot freshly baked foods by speeding-up the production times.

Less

waste

Prepare large quantities of food in order to store and regenerate them as just baked, at any time and without waste, depending on customers orders.

Working 24/7,

linked cycles

also at night.

Set the working cycles with cold and hot functions in automatic linked sequence. This allows you to choose the most suitable cycle for the food to be processed and to start processing even at night so that the preparations are ready in the morning. Time is optimised while respecting the organoleptic qualities of the food.