Up to 2 EN 60x40 trolleys

Maximum internal space 670x1050 mm. It can accommodate 2 trolleys EN 60x40 or 1 trolley EN 60x80. The ramp provided facilitates the entry and exit of the trolley.

Advanced air

circulation system

The innovative air circulation system ensures an extremely constant internal temperature throughout the compartment. The supply air conveyor and the return air casing are designed to ensure a uniform temperature for both the top and bottom trays. The result? Impeccable leavening and unprecedented cavity formation.

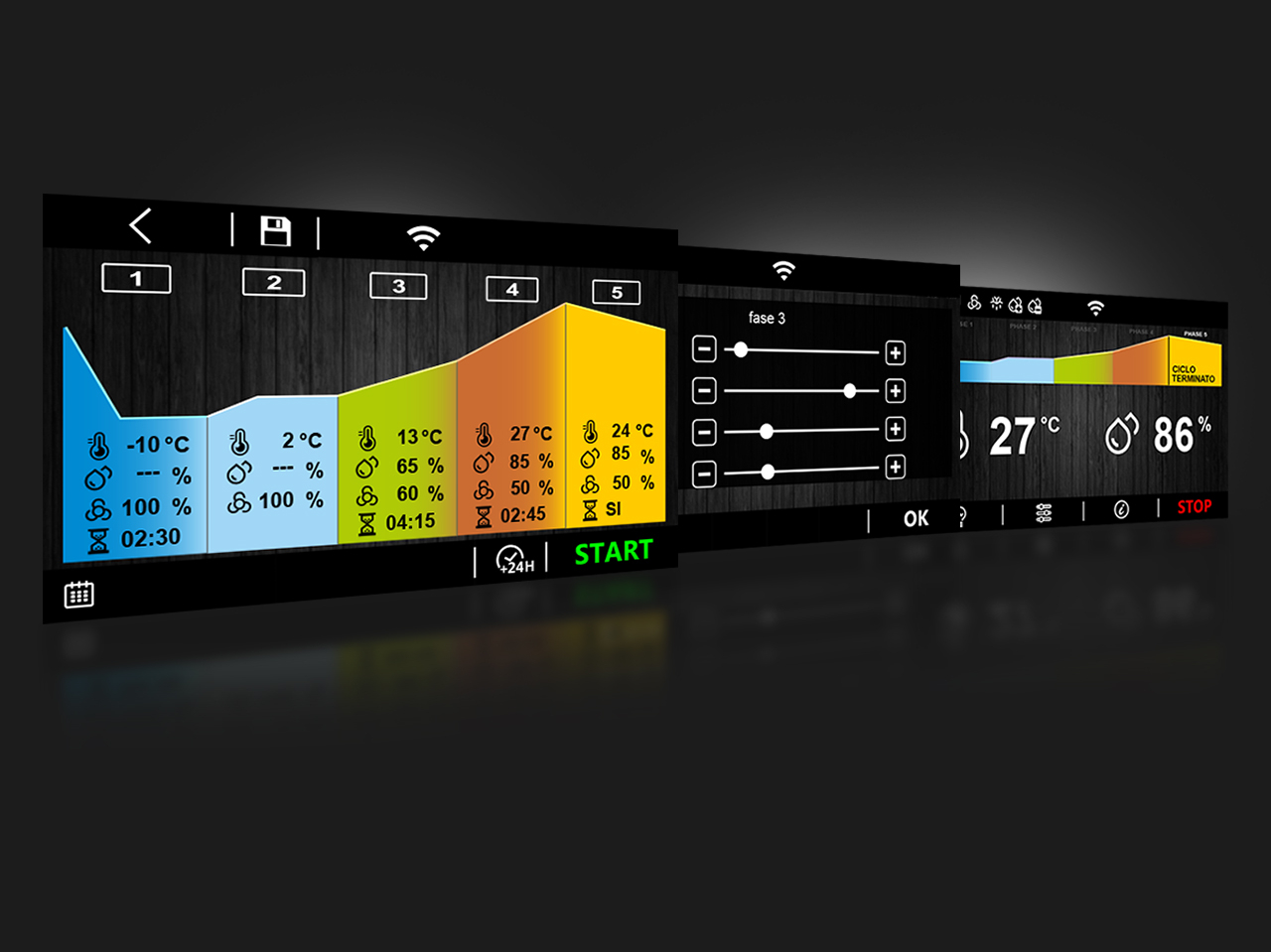

Display touch 7”

Simple and intuitive multilanguages

graphic interface.

- Automatic and

manual cycles - Manual storage cycle

- Cycle graphic

visualization - 100 recipes

Advantages

In the artisan labs the need to have constant quality, certainty of leavening times and possibility of higher product rotation leads bakers and pastry chefs looking for new solutions.

Reduction of

night work

Increase productivity during daytime and significantly reduce the personnel costs.

Quality all

year long

Slow and progressive leavening, reached through Evolution, improves the flavour, the digestibility and the conservation of the product.

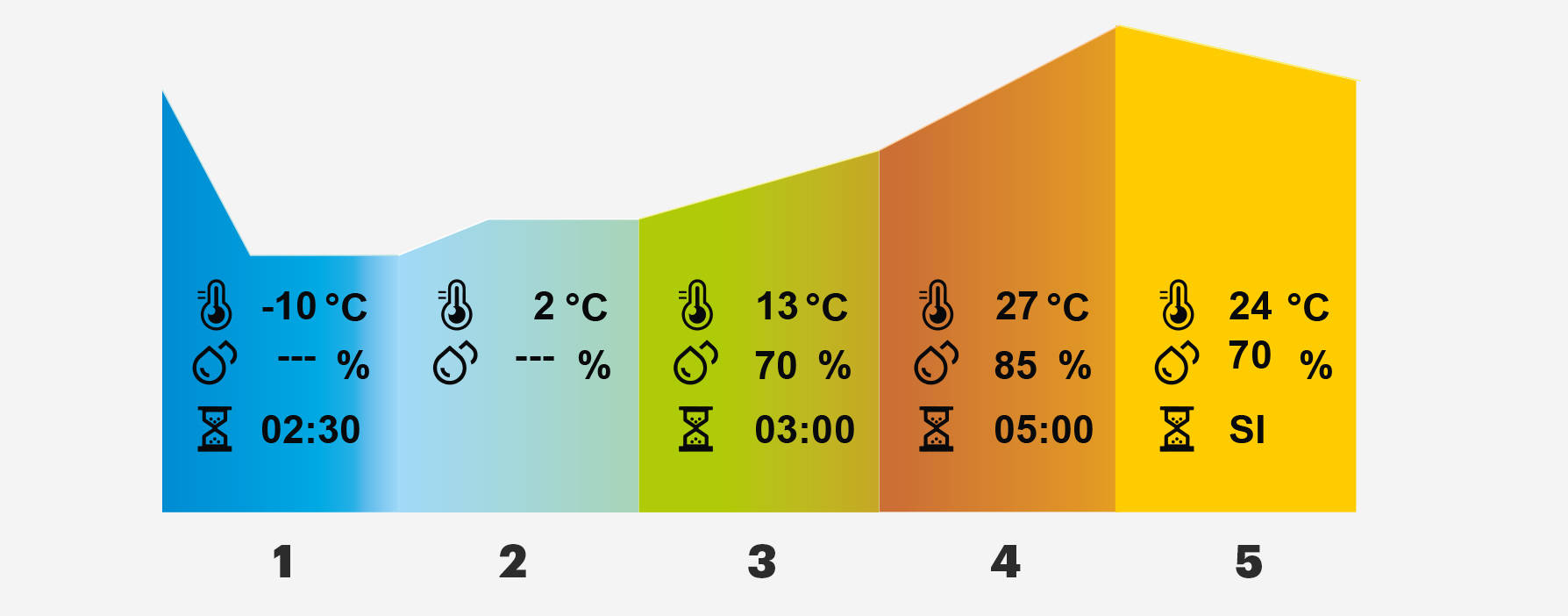

A revolutionary time management

Step 1

Block

By temperature -5° -10°C to stop leavening. Low temperatures are used to block or slow down the fermentative activity of yeast.

Step 2

Storage

The dough is kept round 1 or 2°C temperature. The cycle phase is automatically adjusted according to the end of proving time.

Step 3

Awakening

Temperature begins to raise until 12°C so that the yeasts can gradually resume their activity.

Step 4

Leavening cycle

The dough leavening takes place at a progressive temperature and controlled humidity.

Step 5

Leavening block

This optional cycle keeps the product stable until the baking.

Humidity under control

Each model is equipped with a humidity generation system to set the relative humidity between 60% and 95%. Humidity control avoids dough dehydration and cracks on the surface as well as improving the quality of the product during the leavening phase.

Ideal temperature

Possibility of generating heat (up to +40°C) and cold (up to -22°C) and obtaining the ideal temperature to trigger the yeasts and to have a uniform honeycomb but also to conserve at low temperatures.

Energy saving

High performances and low consumption thanks to the monoblock unit equipped with R290 as refrigerant gas.

Active air

Uniform distribution of the air to ensure a perfect result of the dough.

Smart

solutions

Technical details that

make the difference.

Internal Structure

Rounded corners and bumpers, solutions that guarantee hygiene and safety

Ergonomic handle

Full-height handle with ergonomic grip

Self-closing Door

Automatic soft-closing with sturdy hinges